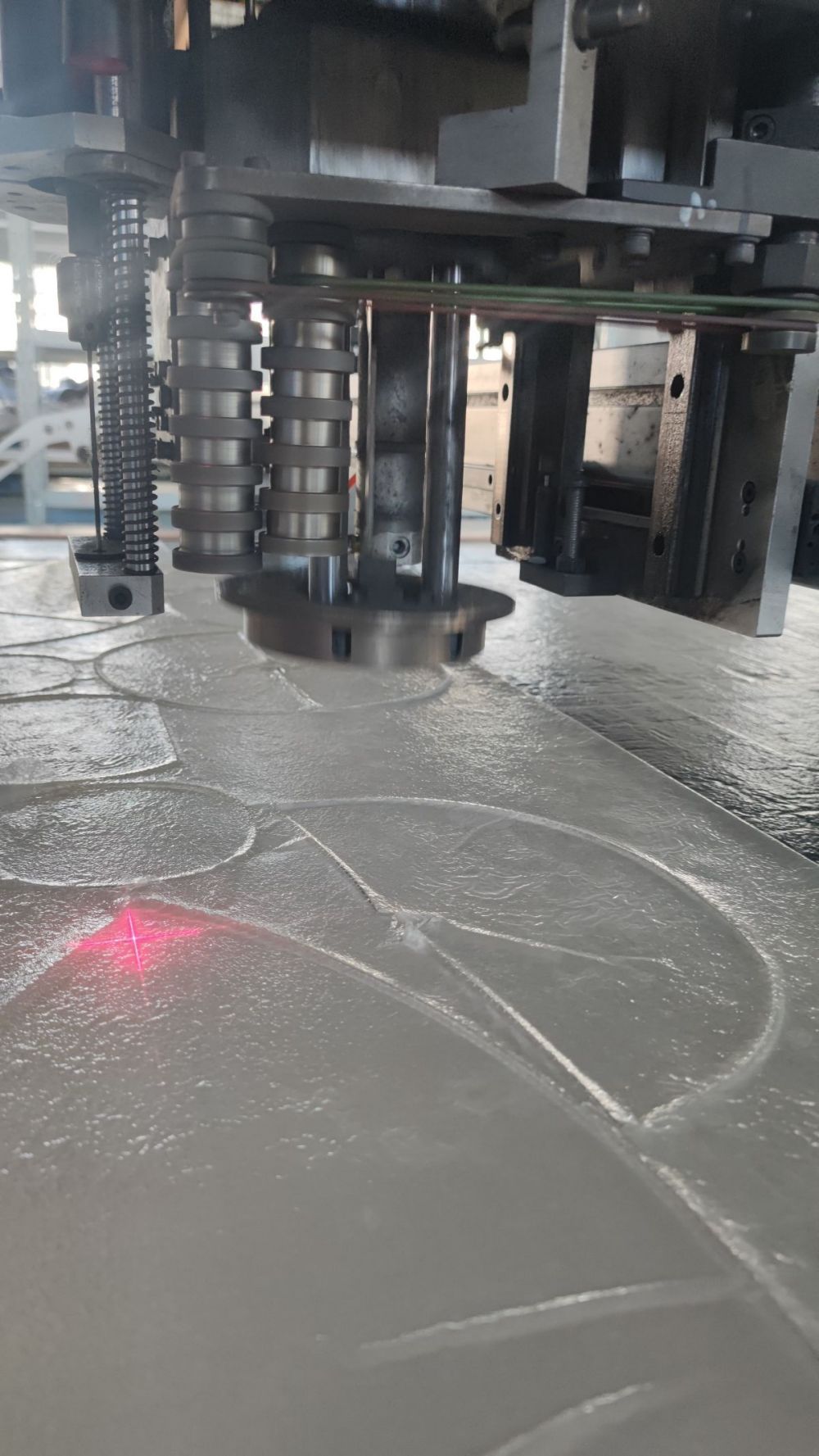

LION ARMOR Group adheres to the concept of providing customers with high quality ballistic protection products, strictly control each production process.By using automatic cutting machine, the design of cutting raw material process is entered into a CAD system that enables easier edit design, lower wastage and longer electronic storage. The 3 automatic and 2 manual cutting machine can flexible handle different order requirements and ensure most project schedule.

In the field of advanced protective equipment, bulletproof vests and helmets are considered must-have equipment for law enforcement officers and military personnel. These lifesaving products are designed to provide maximum protection against projectiles, ensuring the safety and well-being of the wearer. To meet the growing demand for these products, the company is constantly innovating and integrating cutting-edge technologies into its manufacturing process. One of the innovations was the addition of the automatic cutting line.

Cutting raw material designs for bulletproof vests and helmets can now be entered into computer-aided design (CAD) systems by incorporating automated cutting machines into the production process. This technological advancement has revolutionized the industry, making it easier to edit designs, reducing material loss, and ensuring longer electronic storage times. The use of automatic cutting machines has been a game changer for manufacturers, allowing them to maintain precision and accuracy while significantly improving overall efficiency.

Renowned for its expertise in producing ballistic helmets, vests, panels and shields, our company has embraced this cutting-edge technology. We have successfully integrated automatic cutting machines into our manufacturing process, thereby increasing production capacity. Currently, all of our ballistic products are cut using these advanced machines. However, we do have some manual cutting machines available for special custom small batch orders or sample requirements.

As demand for bulletproof vests and helmets continues to surge, many countries are investing in bulletproof production lines. These countries are now adopting automatic cutting machines to cut various materials for the production of bulletproof equipment. Realizing the importance of this trend, our company actively participates in technology transfer negotiations.

There are several advantages to integrating an automatic cutting line. First, it allows manufacturers to be more flexible in handling different order needs. With three automatic cutting machines and two manual cutting machines, we can easily meet different needs while keeping most projects on schedule. Automatic cutting machines ensure accuracy and precision, minimizing errors and saving valuable production time.

Second, the use of automatic cutting machines optimizes the use of materials, reduces waste and enables cost-effective production. A CAD system integrated with the machine ensures that each part is cut with the highest precision, allowing optimum use of the material. This not only helps minimize costs, but also enables a more sustainable manufacturing process.

Finally, adding an automated cutting line can improve turnaround time. With a faster, more efficient cutting process, manufacturers can complete orders faster and meet tight deadlines without compromising quality. This is critical in markets where efficiency and timely delivery are critical.

In conclusion, the integration of automatic cutting lines has revolutionized the manufacturing process of bulletproof vests and helmets. It significantly enhances production capacity and enables manufacturers to handle different order demands more efficiently. By reducing material loss and optimizing storage, automated cutting machines contribute to sustainable manufacturing practices. With the increasing demand for bulletproof equipment, automatic cutting production lines are imperative. Our company is at the forefront of this technological advancement and is actively involved in technology transfer negotiations. We invite all interested parties to consult with us and take advantage of our expertise in this field. Together we can further revolutionize the production of bulletproof vests and helmets to keep those who protect us safe.

Post time: Jul-05-2023